20-5-02 Rebuild for the Wars

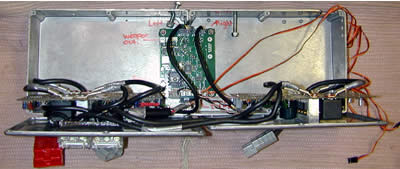

This is the new Speed control set up. The entire system is now housed in these die cast boxes, and links to the real world via 3 anderson connectors , and 2 RC leads to the Rx.

The new interface sits centrally in the case mounted on rubber diablo mounts to damp out vibration. The 4QD speed controllers are mounted directly to the lids with brass screws and heat sink compound. I have plans to add a fan/ filter set up, but to quite honest the ncc70's don't get hot enough. (Need bigger controllers, or more volts at the very least)

The same connectors that ran to the DCI, now connect the speedies to the new board, one for the left motor, one for the right. The pink and black wire take power directly from the battery, (so no need for Rx batteries), and convert it to a useable Rx voltage. The other two connectors run to the Rx. There are 5 input connectors, 2 drive channels and 3 weapons.

And this is what that tiny 4"x4" board replaces...

2 servo's connected to potentiometers, plus brackets.

A servo and microswitch connected to a failsafe.

A DCI interface board.

A powertrac Rc switch

A 4.8v Rx battery pack (not shown).

Once the board was mounted,the whole system takes about 15-20 minutes to setup, has reassuring led's letting you know what's going on. The performance difference is quite marked, previously there was a small but noticeable lag, from the servo twisting the pot to action and speed control response. Now the response is instant, giving a very precise and accurate control. I ran the first real test at at evening "demonstration" to the local church youth group, and it went very well.

With the controls sorted I decided I really should get ready for Robot Wars. Rumour has it the qualifiers are in the first week of July, which gives me just short of 6 weeks to get up to speed.

I started the afternoons efforts by weighing the whole setup. With full armour kc2 weighs around 110kg. I need to actually ADD metal, to make some outriggers at the back, to give a leverage point for the lifter, so I'm going to have to remove something substantial. The only option without going for a complete new chassis is to chop off the whole front of the robot, so I drilled out the rivets holding some of the lexan in place, and wheeled out plasma cutter. I finished the initial surgery off with a 9" angle grinder, and lugged the chassis back to the blacksmiths shop, where KC2 lives at the minute. The steel removed weighs in at around 9kgs so I still need to trim things down. The most obvious option is to trim down the ally plate armour, which really does weigh a lot.

Comments